It is recommended that you update your browser to the latest browser to view this page.

Please update to continue or install another browser.

Update Google Chrome

It is recommended that you update your browser to the latest browser to view this page.

Please update to continue or install another browser.

Update Google ChromeKASERA is a leader in manufacture and development of plate heat exchangers, we have one of the most extensive product ranges on the market. Our product diversity ranges from gasketed to brazed and even fully-welded plate heat exchangers. KASERA focuses on customer orientation, highest quality standards, flexibility and advisory skills important benefits a company of just the right size is able to offer.

KASERA offers a wide range of plate heat exchanger (PHE) solutions with optimum thermodynamic designs for different industries and virtually all applications.

What is a Plate Heat Exchanger?

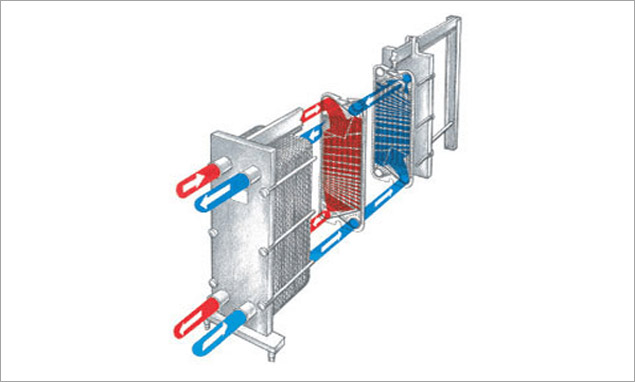

The plate type heat exchanger is the most efficient type of heat exchanger with its low cost, flexibility, easy maintenance, and high thermal transfer. WCR plate corrugations are designed to achieve turbulence across the entire heat transfer area. This produces the highest possible heat transfer coefficients with the lowest possible pressure drop, allowing for close temperature approaches. Subsequently, this leads to a smaller heat transfer area, smaller units and in some cases, fewer heat exchangers. This benefits the customer tremendously by requiring less space, reduced secondary flow rates and smaller pumps.

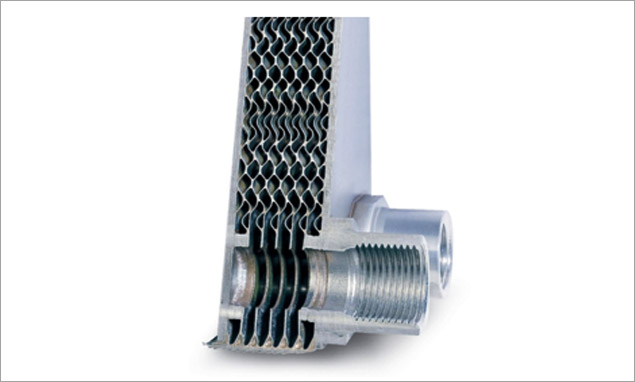

Brazed Plate heat exchangers are used in many industrial and refrigeration applications.Our brazed heat exchangers offer best solutions for the greatest possible range of applications. We choose between copper- and nickel-brazed plate heat exchangers depending on the field of application. We look for the most economical solution from the various sizes and diverse accessories available to us and adapt them precisely to your requirements with customized connections. Brazed Plate heat exchangers are efficient and compact, making them an excellent economic choice.

The Plate & Frame heat exchangers reveal what passion, scientific curiosity and technological expertise can achieve. Plate & Frame heat exchangers use high quality gaskets and design to seal plates together and protect against leaks. Plates can easily be removed for cleaning, expansion, or replacing purposes, drastically reducing maintenance costs.

Welded plate heat exchangers are similar to plate heat exchangers, but instead the plates are welded together. They are extremely durable, and are ideal for transferring fluids with high temperatures or corrosive materials. They are particularly robust and require only minimal cleaning and servicing. The design advantages thus come into play in areas in which in addition to the output, load capacity is also required.